Creating a new thread for my interest in mining with the RTX3090. This thread will be useful for other people doing the same as me, people will search and find this thread.

Both the RTX3080 and 3090 GFX cards from Nvidia have temperature monitoring on the DDR6X RAM chips. These chips run extremely fast, and taking a lot of power. they are clocking at 2500Mhz, and are quad data rate chips so effectively working at 10Ghz. There are 24GB of these chips on the board, spread across both sides of the PCB (RTX3090), only 10Gb on the 3080.

When they get too warm the GPU throttles back to protect things. The thing is their operating temperatures are 95degC, and people have seen them up to 110deg C. You can underclock the RAM to keep it a little cooler.

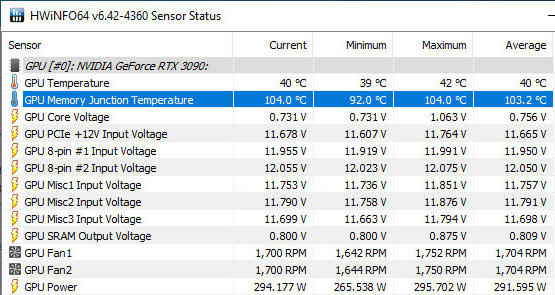

How do we know the temperature of the RAM chips? Well using HWINFO64 it is a very useful tool. It is free, and lets you analyse soo many parts of the PC in detail.

This is too high for my liking. GPU is working pretty much flat out and that's only 40deg C (12degC room temperature). If I can get the ram chips down to 60degC I would be well happy.

So where are the RAM chips located?

On the side of the board around the GPU, the 12 unlabelled squares. These chare the same large heatsink as the GPU, so shouldn't be the issue, unless the thermal pads to the heatsink are not great.

There are also 12 RAM chips on the rear. these have thermal pads to the back plate. There is no real heatsinking on these part from the backplate.

What temperature do we see on the backplate?

So almost 60degrees on the backplate. Why so low? Why do we see 100 on the chips? Perhaps we are loosing 40degrees in the thermal conductivity to the pads. This could be improved by using thinner thermal pads. I'm sure it can be improved. there is no real heatsinking on the back plate. A bit of an oversight in the design.

Thinking of removing the black back cover. Replacing it with a solid 3mm thick sheet, may need to use spacers to get it in the right position. Then I'll screw on a 100x100mm heatsink, countersunk and flat on the inside. The screws wont be on top of the RAM chips, want to keep this part as flat as possible.

The current back cover does have heat transfer pads. I don't know how thick they are, but there could be room for improvement here.

So below is my plan.

Black heatsink, joined to the 3mm thick copper sheet. Then raised copper pads that the thermal pads sit on. The reason for the raised copper bits is that there are other components under the back cover that are higher than the RAM, like SMT capacitors, so the back cover will be resting on them.

I should get all the parts this week, so will be attacking this at the weekend. I'll get many photos during the creation.

Both the RTX3080 and 3090 GFX cards from Nvidia have temperature monitoring on the DDR6X RAM chips. These chips run extremely fast, and taking a lot of power. they are clocking at 2500Mhz, and are quad data rate chips so effectively working at 10Ghz. There are 24GB of these chips on the board, spread across both sides of the PCB (RTX3090), only 10Gb on the 3080.

When they get too warm the GPU throttles back to protect things. The thing is their operating temperatures are 95degC, and people have seen them up to 110deg C. You can underclock the RAM to keep it a little cooler.

How do we know the temperature of the RAM chips? Well using HWINFO64 it is a very useful tool. It is free, and lets you analyse soo many parts of the PC in detail.

This is too high for my liking. GPU is working pretty much flat out and that's only 40deg C (12degC room temperature). If I can get the ram chips down to 60degC I would be well happy.

So where are the RAM chips located?

On the side of the board around the GPU, the 12 unlabelled squares. These chare the same large heatsink as the GPU, so shouldn't be the issue, unless the thermal pads to the heatsink are not great.

There are also 12 RAM chips on the rear. these have thermal pads to the back plate. There is no real heatsinking on these part from the backplate.

What temperature do we see on the backplate?

So almost 60degrees on the backplate. Why so low? Why do we see 100 on the chips? Perhaps we are loosing 40degrees in the thermal conductivity to the pads. This could be improved by using thinner thermal pads. I'm sure it can be improved. there is no real heatsinking on the back plate. A bit of an oversight in the design.

Thinking of removing the black back cover. Replacing it with a solid 3mm thick sheet, may need to use spacers to get it in the right position. Then I'll screw on a 100x100mm heatsink, countersunk and flat on the inside. The screws wont be on top of the RAM chips, want to keep this part as flat as possible.

The current back cover does have heat transfer pads. I don't know how thick they are, but there could be room for improvement here.

So below is my plan.

Black heatsink, joined to the 3mm thick copper sheet. Then raised copper pads that the thermal pads sit on. The reason for the raised copper bits is that there are other components under the back cover that are higher than the RAM, like SMT capacitors, so the back cover will be resting on them.

I should get all the parts this week, so will be attacking this at the weekend. I'll get many photos during the creation.